DI-SEP SX Filters Make Copper Mines More Pure

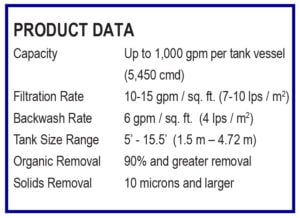

Pioneered in 1980, Smith & Loveless DI-SEP SX Filters are high volume pressure filters designed exclusively to purify electrolyte fluids in copper mining/electrowinning facilities. DI-SEP SX Filters installed prior to the electrowinning stage first remove organic materials present in the electrolyte, typically achieving removal efficiencies of greater than 90 percent. Because the commercial success of copper is dependent on its final quality, DI-SEP SX Filters serve as an important step in yielding a finer copper product.

DI-SEP SX Filter systems, which comprise tank vessels, a piping/valve skid, and PLC-driven controls and instrumentation, have been installed at numerous copper SX-EW mines throughout North and South America, Australia, and now, Europe.

Features & Benefits

- Proven process and systems backed by established engineering

- Easy access for maintenance located in the front of the system

- Open galleries can be included for easier and safer passage inside the filter

- Custom-designed control panel with interface terminal and data ports

- Unique design allows low shipping, instalation and maintenance costs

Models & Shipping

The Smith & Loveless DI-SEP SX Electrolyte Filter comes in the standard configuration and two new configurations, modular and container. All three styles enable the fastest and most economical shipment and installation possible.

In containerized shipping, the entire DI-SEP SX Electrolyte Filter system minus the filter vessels is shipped assembled in standard shipping containers. This means more economical overseas shipment and less risk of damage during transit. In order for the system to be containerized, the valve and piping galleries are built less than 8′ (2.4 m) high. Containerization is the most economical method for overseas shipment.

In modularized shipping, the valve and piping gallery is rack-mounted and shipped separately from the vessels. It is complete with all valves, tubing, instrumentation and conduit in place. The modular style’s slim profile enables the DI-SEP SX Electrolyte Filter to be successfully transported, even over narrow mountain roads.

DI-SEP System Features

User Friendly Design

Components that may require maintenance are located at the front of the system for easier access. Open galleries can be included for easier and safer passage to the filter components.

Flexible Shipping

Systems deliver in standard and container configurations, enabling the fastest and most economical shipment and installation possible. Smith & Loveless assists every step of the way.

Smart Controls

The custom-designed control panel typically features an operator interface terminal, data highway and modem communications.