Solvent Extraction Filter Solutions for Mines

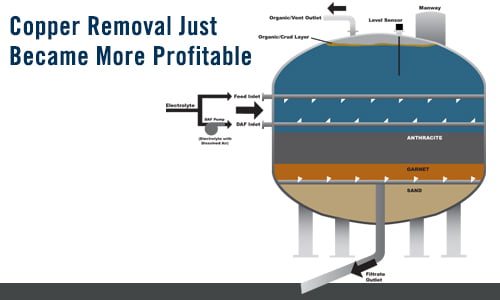

Pioneered in 1980 by fluid separation and handling expert Smith & Loveless, DI-SEP SX Filters are high volume pressure filters designed exclusively to purify electrolyte fluids in copper mining/electrowinning facilities. DI-SEP SX Filters install prior to the electrowinning stage to remove organic materials present in the electrolyte. Because the commercial success of copper is dependent on its final quality, DI-SEP SX Filters serve as an important step in yielding the finest copper product at numerous SX-EW mines all over the globe, including Chile, Peru, Australia, Mexico, Canada, the United States and Spain.

Smith & Loveless also advances the Solvent Extraction (SX) Filter market with DI-SEP SX-DAF technology. Copper SX-EW mines throughout North and South America that upgrade with DI-SEP SX-DAF will significantly increase filtration performance over conventional SX filters — with removal efficiencies up to 99% — while more than doubling the throughput.

DI-SEP® SX-DAF

Increase SX filter performance with removal efficiencies up to 99% and doubling the throughput, with the DI-SEP® SX-DAF.

DI-SEP® SX Filter

The DI-SEP® SX Electrolyte Filter removes 95-99% of organic material, which aids in producing extremely high electrolyte quality.

Design Benefits

- Superior Filtration Efficiency (Typical 99% organic removal)

- Significantly Increased Throughput (2x-6x)*

- Less Frequent Backwash – Less Downtime and Loss

- Also Retrofits into Existing SX Filters (any brand)

- No Increases to Tank Side Wall Required

- Durable, Robust Design That Will Last

- Available for All Tank Sizes

*Successfully tested up to 6X normal flow

Maintain Spare Parts to Optimize SX Performance

Like any process equipment in corrosive environments, the key to maintaining optimal DI-SEP® SX Filter performance over time is maintaining an essential parts inventory and media supply. Taking a proactive approach as recommended by your O&M Manual significantly reduces operational downtime, essentially providing inexpensive insurance against lost production time.